Emerald K3 and Tech Edge 2J1

Managed to spend some time in the workshop over the weekend. One of the pending jobs was to install a wideband lambda sensor. There were 3 options

Innovate LC-1,

DynoJet Wide Band 2 or

Tech Edge 2J1.

The LC-1 has received some bad press recently, Emerald themselves are no longer recommending it even though it is the only product documented in the K3 manual. Another reason for not using the LC-1 is the messy installation. A 100 ohm resistor needs to be placed between the LC-1 out and K3 due to the sensitivity of the LC-1 output. Also the calibrate switch and status LED are remote from the unit itself requiring additional wiring and bracketry.

Next up, the DynoJet. Good kit, just too expensive.

That leaves the Tech Edge 2J1. This is very impressive kit at a great price.

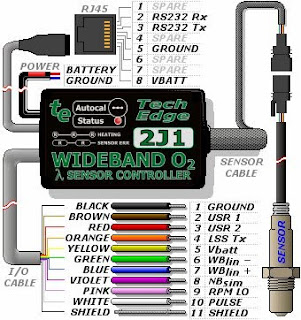

Installation is a simple 4 wire hookup.

2J1 Power cable goes to a 5 amp ignition switched live and ground. When I make an ECU loom, I use a single ignition switched relay plugged into a holder that incorporates 3 fuses. I use one of these fused lives to power the lambda sensor and speedo sensor. The earth is connected directly to the battery along with the ECU.

2J1 I/O cable provides 0 - 5 volt wideband output WBlin+ on the blue cable and ground reference for wideband output WBlin- on the green wire. WBlin+ goes to any user defined analogue input. I chose AuxIn35. WBlin- connects to pin 30 along with the temp and throttle position sensors. It is interesting to note that WBlin- is an input into the J21. WBlin+ signal will generated with reference to WBlin-.

The Tech Edge website has a

page describing the differential output of WBlin+. Note that the 2J1 does not have a GND SHUNT jumper. The default configuration is perfect for the Emerald K3. However if connecting the 2J1 to a single-ended logger or ECU, you'll have to link the black and green wires in the I/O cable.

Next task is to tell the Emerald K3 about the sensor. In the K3, AFR / Lambda Input Configuration Screen, set the input source and enter the values below.

Input Voltage AFR

0 9

1 11

2 13

3 15

4 17

5 19

Stoic 14.7 AFR = 2.85 V which is almost in the middle of the voltage range making the default a good compromise.